Not all modules are available in every version

FILOU NC – Module |

FILOU-NC – the CNC-Toolbox for 2.5D millingLike a toolbox FILOU-NC offers a lot of tools to make the creation of NC-Code a lot easier. Lots of CAD-Tools, a powerful Manager, lots of CAM-Tools, a CNC-Editor with an attachted Backplot, a 3D-Simulation with an Analysis-Tool and the transfer to the machine, all this is completed by a smart macro-programming for Macros, Cycles and postprocessors. Everythin in just one CAD/CAM Solution. Everything, from drafting to the transfer to the machine, can be done in FILOU-NC. But that is not a must, still you are able to import or export DXF files. CNC-Programs (max. 3 axis) can be imported and simulated. Depending on the Version FILOU NC16 contains different modules with a different count of tools. Here you can find a versions comparison.. |

|

2D-DXF Drafting The basis for the CNC programs is always a DXF-drawing that you either create directly in FILOU-NC or import a DXF file from your existing CAD program. Existing DXF drawings are checked by FILOU-NC for further use. Splines, for example, are converted into approximate arcs. Imported drawings can be edited with the existing CAD tools in FILOU-NC. This way, you have the option of adding vector TrueType font. |

|

CAM For the creation of NC-Programs from geometry. Lots of tools for editing contours, pockets, circular pockets, milling text, freehand milling, drilling with path-optimisation and if desired machine specific cycles and much more. Along comes a tool-management with cuttingdata-calculation. |

|

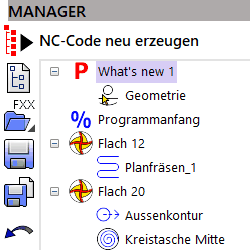

In the Manager every processing step, even the geometry, are managed and stored in a project. Afterwards, the technology parameters can be changed with the help of the manager. Missing parts can just be added or edited without having to deal with the actual NC-Code – Now that’s comfortable CNC-Programming. |

|

CNC-Editor + Backplot A modern CNC-Editor that processes nearly unlimited large CNC-files. Besides conventional commands there are CNC-specific functions. The editor is associative connected to the Backplot, that displays the created toolpaths as a 3D-Wireframe. One click on a toolpath will make the editor jump to the corresponding line in the CNC-Code. It interprets the finished program (G-code, Heidenhain Klartext, ISEL NCP HPGL, etc.) even not in FILOU-NC created programs can be edited in the Backplot. |

|

3D-Simulation + Analysis In the 3D-Simulation, the NC-code from the CNC-Editor is simulated in 3D. This way even CNC programs not created in FILOU-NC (max. 3 simultaneous axis) can be simulated in 3D. It is very simply: Analyze NC code, define the stock, assign tool, start Simulation. Done. With the affiliated analysis, among other things, the estimated machining time for the program will be calculated. |

|

RS232-Transfer With the built-in serial interface you are able to transfer CNC programs to and from a machine with the appropriate interface. You can create any number of machines that can then be activated when needed. |

|

Macro-Programming With the built-in macro programming you are able to write your own CAM macros. You can also individually adjust the postprocessor for nearly all machine controls and their own functionality. |

|

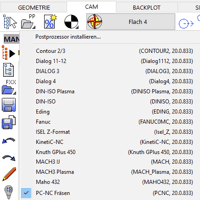

Postprocessors For most common machines, standard postprocessors are included. If none of the supplied post processors fit to your control, we can make a custom postprocessor for you (Only in FILOU-NC/OPEN). |